Covestro Introduces New Products Made from Recycled Plastics at Formnext Connect

These products seek to contribute to help the 3D printing industry to become more circular.

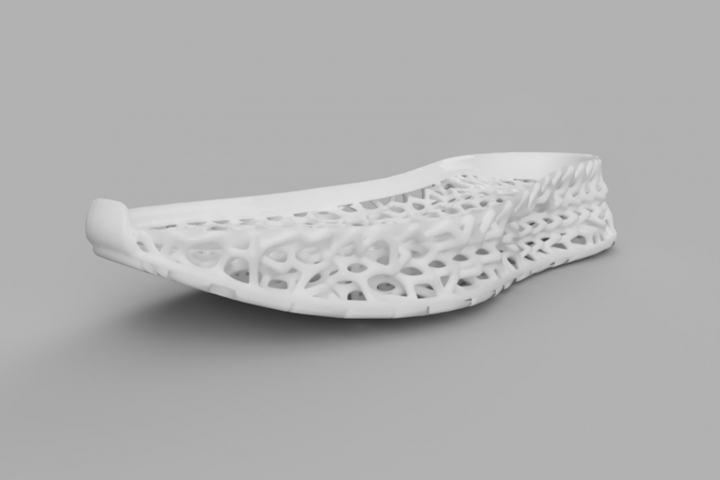

This shoe insole was printed by selective laser sintering from a partially bio-based thermoplastic polyurethane (TPU) by Covestro.

During the virtual trade fair (November 10-12), Covestro will present products entirely dedicated to the circular economy. This includes products made from alternative raw materials, such as recycled plastics and COâ‚‚-based cardyon brand products, which the company says will contribute to the development of the 3D printing industry to become more circular.

Covestro will also provide an outlook to a range of Addigy materials for common 3D printing processes at Formnext Connect. The developments will be presented in an interactive expert session in the virtual Covestro studio on November 10, starting at 11:00 a.m.

"Nowadays, superior manufacturing technologies are no longer enough to produce truly sustainable products," says Patrick Rosso, global head of additive manufacturing at Covestro. "We want to boost the circularity of our products while preserving their excellent properties. That's why we are currently developing new, more sustainable products which are already in the testing phase."

These include pellets and filaments made of partially recycled plastics. Some of the raw materials for the recycled plastics are post-industrial waste from Covestro's manufacturing facilities and can be used as filaments for 3D printing after reworking. One of the products developed from recycled plastic is a polycarbonate blend and, like other polycarbonate-based materials, is suitable for applications that require a high temperature resistance.

Equally promising as building blocks for sustainable 3D printing products are polyols of the cardyon brand, in which COâ‚‚ replaces some of the petrochemical raw materials previously used. These can for example be used to produce thermoplastic polyurethanes (TPU), which can be used as powders or filaments in additive manufacturing.

In addition, Covestro is currently developing partially bio-based products for 3D printing, in which almost 50% of the carbon content is derived from biomass. One such material has already been used to print a shoe insole using selective laser sintering (SLS).

Related Content

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.