Collaboration Creates Recycling Loop for Multilayer PET

Water-based adhesive makes packaging film easier to delaminate.

The European Green Deal requires all packaging to be reusable or recyclable by 2030. The regulation is perceived as particularly challenging for multilayer packaging, since its layers first need to be separated before entering recycling streams.

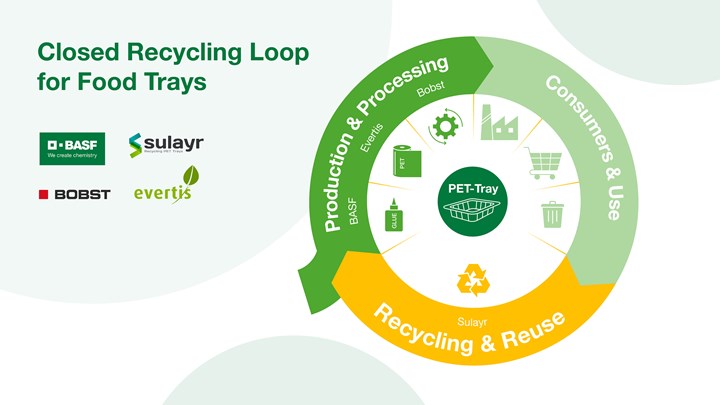

Collaboration throughout the value chain is required for circularity.Photo: BASF

A multilayer film produced by , comprising PET and PE layers, laminated with a BASF Epotal water-based adhesive and processed with a coating system, is produced for various applications, including thermo-formed food trays. After use, collected product can be used as a raw material by . Sulayr has a process for separating the layers, recovering the PET for delivery to Evertis and other film producers. The process can be applied to both post-consumer and post-industrial product.

Sulayr has been able to separate multilayers since 2009, but the speed and cost-effectiveness depends on the debonding of the films. The new Epotal® water-based adhesive from BASF simplifies the process, enabling quicker and easier separation than is possible with solvent-based adhesives.

BASF has another new adhesive type currently under development, which promises to make the delamination process even easier under certain conditions.

Related Content

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.