Aerosol Spray Cap is Recyclable

Dutch company Weener Plastics has developed a mono-material spray cap for easy recycling.

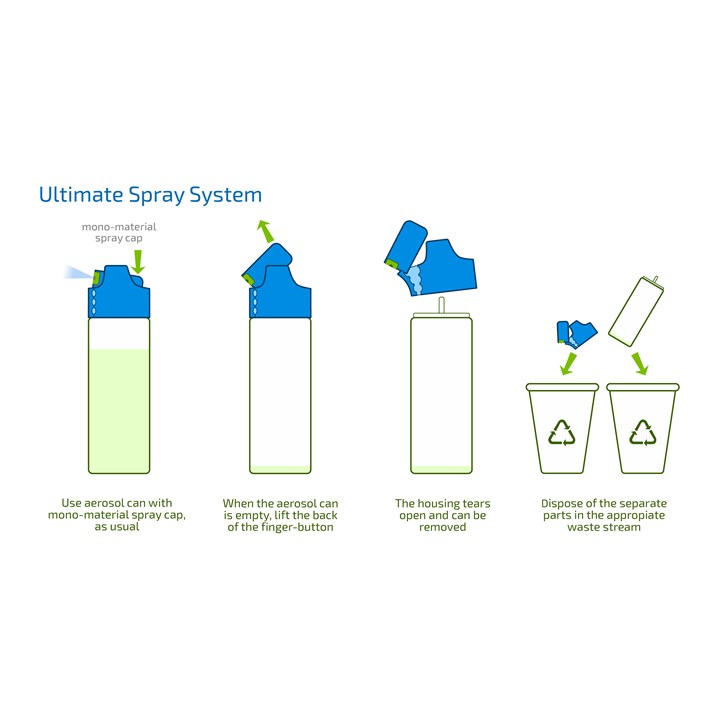

has developed a fully recyclable aerosol spray cap, called the Ultimate Spray System, which consists of a two-piece spray cap made from a single material. According to Weener, the cap offers spray performance equal to proven, conventional spray caps.

Mono-material: PP Insert

To achieve refined spray patterns for specific application requirements, aerosol products often use a spray cap with an insert. Traditionally, inserts are made of PMMA, which cannot be recycled and disrupts waste streams. To address this, Weener makes both the insert and cap from PP, which can be recycled in standard waste streams. For true circularity, the cap is also available in recycled PP.

Removable Spray Cap

The PP spray cap can be easily and conveniently removed from the aerosol container before disposal. The finger-button can be lifted, at which point the housing of the spray cap is torn open and can be removed. The separate spray cap and aerosol container can then be disposed of in the appropriate waste stream.

Removal process of mono-material spray cap. Photo: Weener Plastics Group BV

Weener Plastics anticipates adoption of the spray system by customers involved in personal and home care products. Customers will be able to customize the spray characteristics including orifice and spray pattern. The caps fit standard aluminum and tinplate aerosol containers and can be processed on standard filling lines.

Related Content

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.