The Shale Gas Game Changer

Editorial

Processors and resin suppliers alike believe the availability of low-cost feedstock will present huge opportunities in the North American plastics market.

Processors in North America—and likely in other places around the world—are wondering what will happen to resin prices in light of the abundant supply of shale gas in North America. We covered this topic in a feature story, The Boom in Natural Gas: What it Will Mean for Plastics Processors, that appeared on the cover of our November 2013 issue. This comprehensive piece was researched and written by Senior Editor Lilli Sherman.

How the shale gas boom will impact resin pricing is no trivial matter; material expenses account for anywhere from 60% to 70% or more of a processor’s overall manufacturing cost, depending on the process being used.

Back in November, I attended a conference in Chicago that focused heavily on shale gas and how (or whether) the availability of cheap ethane in North America could potentially change the landscape of plastics processing here. It was called the Global Plastics Summit, and was co-sponsored by Houston-based and the , Washington, D.C. I came away from the event with this thought: Shale gas has the potential to be a major game changer and a boon to plastics processing in this continent.

One of the more compelling keynote presentations from this three-day conference was delivered by Greg Jozwiak, commercial v.p. for North America at Dow Packaging and Specialty Plastics; and Scott Farmer, executive v.p. for global purchasing at processing giant In separate presentations, they gave their views on the growth opportunities shale gas will ultimately offer to packaging suppliers.

Both were extremely optimistic. “Shale gas offers plentiful and competitive energy for America,” Jozwiak said. “It justifies new investments and provides opportunity for growth across the plastics industry via core market growth, reshoring, traditional material conversion to plastics, potential to export converted goods, and selective resin export.”

Jozwiak pointed out that in the $173 billion packaging market, plastics have a 35% market share. Polyethylene in particular has a 10% share of packaging. If PE’s share were to increase by just a single percentage point, Jozwiak said, the consequences would be extraordinary. “An increase of 1% translates into 200,000 metric tons of PE consumption,” he said, citing the Smithers Pira study of Packaging in North America to 2017. “That amount alone would require about 28 (film) processing lines.”

But the Dow packaging executive was even more bullish than that. “Core growth (due to shale gas) could boost growth by 2.5%, reshoring 1%, substitution (of non-plastics packaging) by 0.75% and export of finished goods another 0.25%,” he explained. “That’s 4.5% of growth, representing 770,000 metric tons/yr.” Jozwiak added that Dow customers outside the U.S. are looking to establish a manufacturing footprint in America to tap into this potential.

To Berry Plastics’ Farmer, however, much of shale gas’ potential for U.S. processors is tied to how much—or whether—it brings down resin prices. “Resin generally comprises the largest portion of the overall cost to plastic packaging. (Resin) producers are enjoying lower costs due to investments made in the shale boom. Converters are paying, on average, higher prices than in previous years. Lower costs will allow plastic packaging to grow into spaces currently occupied by other substrates. Lower costs will increase domestic manufacturing, bringing products and jobs back to the U.S. Lower costs will create the potential to drive innovation and growth.”

Will prices be coming down? If so, when? The experts can’t say for sure, except that there won’t be any immediate benefit. But you should be ready for the possibility, and the opportunities it might create. And that means you’ll need to evaluate your equipment.

In extrusion, for example, one industry source told me that more than 70% of the 20 billion lb/yr of blown film is currently run on equipment that’s at least 10 years old. It can be argued that if resin costs from shale gas drop even a penny a pound—a decent amount for any processor, particularly those who deal in high volumes—film producers will still be leaving money and opportunities on the table if they continue to run it through equipment that doesn’t offer the latest capabilities in throughput, gauge control, and quality. What would be the point of that?

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreFlexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreRead Next

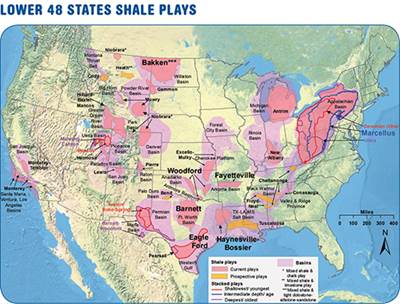

Natural Gas Boom: What Will It Mean for Plastics Processors?

Plentiful shale gas promises to keep domestic polyolefin production costs among the lowest in the world. Whether (and when) you will see savings is debatable.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More