Winners of SPE Auto Innovation Awards in Materials and Body

Lots of "firsts" highlighted the 2015 SPE Automotive Innovation Awards.

Spanning nine categories, the winners of the 2015 Blue Ribbon Automotive Innovation Awards, for which delightedly I was a participating judge, are unique and represent many “firsts”, whether it be metal replacement or a better plastic replacement. Thermoplastics weighed-in in six of the awards, with thermosets featured in two, and a fabric made of 100% recycled PET bottles among the “firsts”.

Take a look at the materials category whose winner was selected the “grand award winner”, as well as the body interior and body exterior winners.

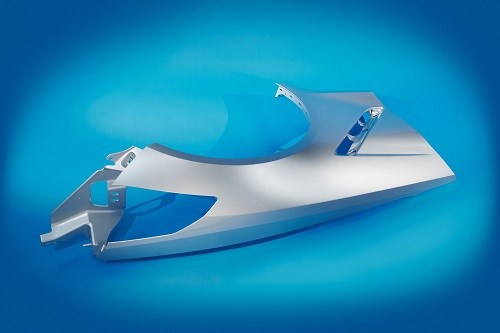

Materials: Ultralight Class A Body Panels

’s 2016 Chevrolet Corvette sports cars feature 21 body panel assemblies, depending on the model, made with the new TCA (tough Class A) Ultra Lite SMC, a compound formulated and compression molded by , Auburn Hills, Mich. With a specific gravity (SG) of 1.2, this SMC compound, offers mass reductions of 28% and 43%, respectively, versus CSP’s 1.6 SG TCA Lite SMC and conventional 1.9 SG SMC grades.

The 19% (>20 lbs) weight savings achieved with the new TCA Ultra Lite vs the earlier TCA Lite was enabled by the use of hollow glass microspheres which replaced traditional heavier fillers such as calcium carbonate, along with CSP’s proprietary surface treatment on the microspheres which promotes chemical bonding to the unsaturated polyester resin matrix. The improved resin/microsphere interface plays a key role in boosting both mechanical properties and adhesion properties for the SMC components. Also touted is improved paint adhesion, especially after humidity or water exposure. Superior surface treatment and paintability are key features of these ultralight Class A body panels which include: doors, decklids (trunks), hatch, door surrounds, quarter panels, fenders, convertible tonneau assembly, and coupe roof bow.

Body Interior: Rear-Seat Folding Head Restraint

The 2015 F-150 pickup features a rear-seat, folding head restraint that eliminates a welded steel structure and replaces it with a single-piece, living hinge thermoplastic core as its main structural component. (Typical rear head restraints use steel underpinning covered in plastic shrouding.) Automotive global Tier I supplier specializing in custom head restraints and armrests and custom molder , both based in Ontario, teamed up to design and injection mold this unique head restraint using a standard random PP copolymer from .

This unique single-piece plastic core results in reduced thickness from 2.56 in. to 1.26 in. for improved comfort and rear visibility, a mass savings of 1.38 lb/vehicle, while significantly reducing manufacturing complexity by eliminating the need for special tooling processes thanks to consolidation of five parts into one. Tooling costs are reduced by $180, with piece price reduced by $1.50/vehicle, while still meeting or exceeding all global safety requirements. Moreover, the technology has been applied to the 2016 Ford Explores and is planned for at least three additional programs.

Body Exterior: Push-to-Release Exterior Serviceability Fastener

The 2015 Mustang features a unique fastener that only requires that you push the center pin to the service position to remove—an 80% reduction in removal time--compared to other easy-service fasteners which have two twist heads to release along with the risk of unintentional removal.

Designed and manufactured by Troy, Mich., the new fastener is made of Vydyne 47H nylon 66 from Houston-based The pin and body are designed not to be easily separated; however, the fastener is reusable, unlike other push pins that become damaged in the process of removal. The part meets the 10-lb insertion ergonomic requirement, and the EU ECE-R04 lighting service regulation, and its low profile meets exterior craftsmanship. It decreases the chance of unintended release: it cannot back out or be removed from the install position without deliberate actions by the customer. Finally, there is a 10% cost reduction in piece cost from comparable service fasteners on the Mustang.

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More