Where Do You Fall On Industry 4.0’s Adoption Curve?

Beyond the hype: how are injection molders applying industry 4.0 today, and what’s coming in the future.

In his 1962 book, Diffusion of Innovations, Everett Rogers first posited the concept of a technology adoption curve that many of us are familiar with more than 50 years later. Five categories of adopters—innovators, early adopters, early majority, late majority, laggards—spread across a bell curve with most falling in the middle three categories.

As interesting as the curve, however, are Rogers’ five stages of technology adoption:

- Knowledge

- Persuasion

- Decision

- Implementation

- Confirmation

It’d be hard to work in injection molding and not have knowledge of Industry 4.0 by now. In fact, at least on a small scale, I’d guess many molders have been persuaded one way or the other and are on the precipice of making a decision about Industry 4.0.

To help those folks along and to hear from companies that have already implemented Industry 4.0 and confirmed its benefits (and challenges), we have created an entire track at (Feb. 27-March 1; Long Beach, Calif.) looking at “Practical Application of Industry 4.0”.

Injection molding machinery suppliers have been at the forefront of Industry 4.0 in our space, and they are well represented in the track with speakers from Arburg, Engel, KraussMaffei and Wittmann Battenfeld. Speakers from these companies will discuss how their customers are already utilizing the power of Industry 4.0 and how molding machines are enabling that utilization.

In addition, we’ll have auxiliary supplier, Piovan, discussing the installation of an Industry 4.0 compliant molding facility here in the U.S., and we will also hear from two vendors of powerful hardware/software solutions to bring 4.0 functionality to the plastics shop floor.

Whether you’re an innovator or a laggard or you’re in the process of gaining knowledge or confirming your decision regarding Industry 4.0, you will stand to benefit from the collective experience of our speakers.

Wednesday, Feb. 28

Practical Application of Industry 4.0

1:30 - 2:00 pm

Installation of an Industry 4.0 Compliant Production Facility in the U.S.

Giorgio Santella, VP service and sales North America, Piovan

Read More about Industry 4.0 and Piovan: Industry 4.0 Connects Auxiliaries

2:00 - 2:30 pm

Real World Examples of Condition Monitoring & Predictive Maintenance

Joachim Kragl, director advanced injection molding systems & processing, Engel

Read more about Engel and Industry 4.0

2:30 - 3:00 pm

Condition Monitoring Systems for Modern Day Work Cells

Markus Klaus, injection molding machines USA division manager, Wittmann Battenfeld

Read more about Wittmann Battenfeld and Industry 4.0

3:30 - 4:00 pm

The Competitive Advantage of Industry 4.0

Willem Sundblad, CEO & founder Oden Technologies

Read more about Oden Technologies and Industry 4.0

4:00 - 4:30 pm

Industry 4.0 Used in the Real World

Juergen Giesow, director of technology & engineering, Arburg

Read more about Arburg and Industry 4.0

4:30 - 5:00 pm

Production Monitoring And Time—The Benefits Of Making Effective Decisions Faster Than Ever Before

Max Preston, director of marketing and sales, Smart Attend

Read more about Smart Attend and Industry 4.0

5:00 - 5:30 pm

Self-Correcting Machines & Auxiliary Integration as Elements of Industry 4.0

Jason Holbrook, sales manager, KraussMaffei

Read more about KraussMaffei and Industry 4.0

There’s more at

Read more about the 2018 version of the industry’s preeminent injection molding conference from previous posts:

Entire Track Dedicated 3D Printing

Emerging Technologies

Special Pre-Conference Hands-On At-the-Press Design of Experiments Workshop

Related Content

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

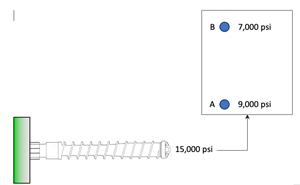

Read MoreUnderstanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreGot Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More