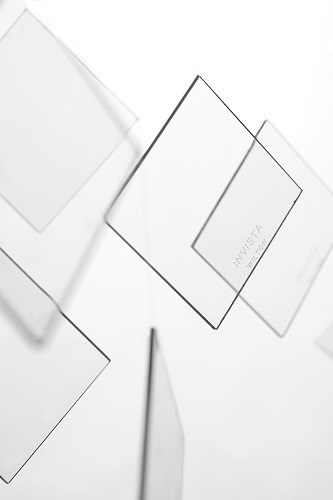

Transparent Nylons That Can Also Be Used As Additives

Dual-function transparent nylons from Invista make debut at NPE2015.

A line of highly versatile semi-aromatic nylons with a unique combination of performance, cost-effectiveness and recycled content were launched by , Wilmington, Del. Moreover, these Novadyn DI/DI transparent polymers can also be used as differentiated blend additives to improve traditional nylon performance. They targeted to bring value to users who require parts that are both transparent and chemically resistant.

“We developed Novadyn DI/DI nylon for transparent applications where polycarbonate struggles with chemical resistance or where more costly transparent polymers may be over-specified. The nylon world in not ‘dry as molded’. In humid environments, Novadyn nylons can boost traditional nylon properties, enable thinner parts, and enhance light-weighting initiatives,” says Allen Reihman, director of new 大象传媒 development for Invista.

As a blend additive for traditional nylons, Novadyn DI/DI nylon significantly improves conditioned mechanical properties for nylons 6/6 and 6, including up to 43% improvement reported in conditioned flexural strength and stiffness.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastic Technology’s Plaspec Global materials database.

Related Content

-

General Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

-

Prices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

-

The Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.