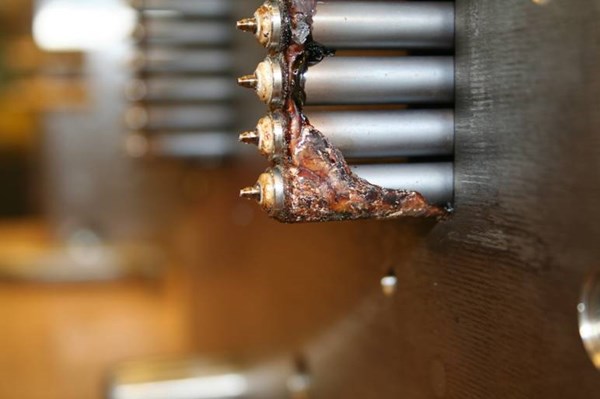

Show Us Your Worst Hot-Runner Leaks!

This leak was detected early with automated controls, to be discussed in an upcoming article. Help show what happens if leaks get out of hand.

They can be even worse than the one pictured here. Detecting and stopping a leak when it is at this early stage is one of the points in an upcoming Troubleshooting article, authored by Gammaflux, on how to cure common hot-runner headaches, including how to prevent small leaks from becoming an expensive mess.

To dramatize the importance of early leak detection and intervention, we invite injection molding readers to submit photos of nasty hot-runner leaks to accompany this article. We know you have the leaks and are betting some of you couldn’t resist documenting them. Send your photos to me, Executive Editor Matt Naitove at mnaitove@ptonline.com by Aug. 15. Thanks!

Related Content

-

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

-

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.