Sheet Extruder Bixby & Bioplastics Firm Green Dot Bolster R&D Partnership

It may be safe to say by now that we can expect to see more and more ‘collaborations’ between plastics processors of a wide range of consumer goods and suppliers of bioplastics as they look for more sustainable options for their products.

It may be safe to say by now that we can expect to see more and more ‘collaborations’ between plastics processors of a wide range of consumer goods and suppliers of bioplastics as they look for more sustainable options for their products. Just last month (Processor’s Edge, PT June 2015), we reported on manufacturer of laboratory disposable products and its collaboration with to switch to the latter’s sugarcane ethanol-based HDPE for its packaging, with plans in the future to use the latter’s ‘Green’ PP for the actual components.

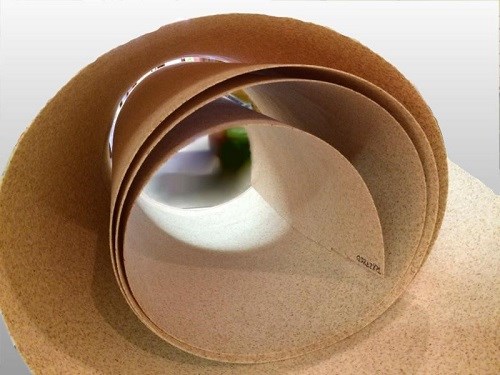

This month, we’ve have the announcement from thermoplastic sheet extruder and laminator , Newburyport, Mass., about its R&D cooperation with bioplastics company , Cottonwood Falls, Kansas. Bixby offers one of the industry’s broadest polymer and substrate selections and prides itself in being able to address the most challenging plastic mono- and multi-layer film and sheet applications.

Green Dot has a full line of biobased and compostable materials sold under the Terratek brand name. One example, on which we have reported, is Terratek GDH-B1 starch-based elastomer which has been used for products like cellphone cases and toys. It is also offered as an impact modifier for PLA—at 10-20% levels, it boosts PLA’s notched Izod by 100-130%, and at 30% addition, it boosts impact strength by 450%. Also cited is an exponential jump in tensile properties, particularly elongation at break.

Meanwhile, it turns out Bixby has been working with Green Dot for a couple of years. The story goes that the latter reached out to Bixby in late 2012, according to Green Dot’s CEO Mark Remmert, for one overwhelming reason: to work with Mark Gagnon, Bixby’s v.p. of R&D/product development.

Remmert praised Gagnon, noting, “Not only is he a recognized leader in plastic technology and plastics processing, but he is also that rare blend of knowledge, experience, energy, passion, and honesty. Marc never tires of explaining processes and investing his time in understanding customer needs and struggles. He is a great guy to work with.” He adds that Bixby’s product development capabilities are exceptional noting that they can go from idea, to concept, to prototype, very quickly. “The product development staff has the experience, equipment, and material know-how, to help customers turn their imagination into reality…and do it quickly.”

Several months after the two companies connected, they ran their first development prototypes for making elastomeric-coated textiles. Since then, the programs developed by the companies have focused on renewable/biodegradable products in textiles, wood-filled plastic composites, foamed extrusions, extrusion-coated natural fibers/fabrics, natural-fiber-reinforced sheet, and elastomeric film and sheet. The companies see their development cooperation as going a long way in helping generate options that have a positive impact on Green Dot’s customers, as well as the environment.

Affirming this, Gagnon notes that Bixby has been enthusiastic about its work with Green Dot because of their unique bioplastic resin technologies. “Their polymers have allowed us to explore and compete against conventional plastics with both elastomeric and rigid extruded applications whereas their biodegradability brings enhanced value to the applications of our end-users. The most exciting fact is that we have not had to sacrifice on performance—either in physical properties or processing—in order to deliver the additional benefits of a true biopolymer.”

For more about Bixby's capabilities, click to this article.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastics Technology’s Plaspec Global materials database.

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreFilm Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreRead Next

On Site: 140 Years…And Growing Stronger

Now in its fifth generation of family ownership, this sheet extruder isn’t all about output. Its focus is on creating solutions in highly customized markets that aren’t immediately associated with sheet.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More