Plasmatreat Building New Open-Air Plasma Units for Personal Protection Equipment

Coronavirus pandemic has spurred Plasmatreat to develop two new applications.

As with several other suppliers of plastics equipment and materials, we recently received notification from Plasmatreat North America, subsidiary of 25-year old Plasmatreat GmbH, Steinhagen, Germany, that it is open for 大象传媒 during this pandemic. Moreover, President and CEO Hardev Grewal revealed that the company is working on two new plasma applications geared to addressing the growing concerns about a shortage of disinfecting agents and personal protective gear (PPEs).

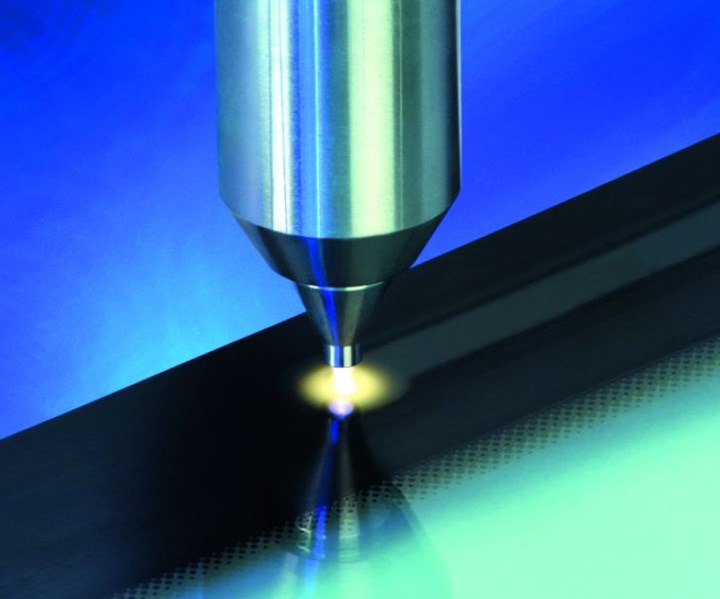

First, the company is building new Openair-Plasma systems to disinfect and sterilize PPEs such as face masks and garments for their safe reuse. Second, the company is also producing plasma-activating water to treat surfaces. In addition, Grewal is asking customers and others in the industry to contact him if they are aware of other opportunities for which the company’s technology can be used to help. “We have amazing people here at Plasmatreat that deeply care about your well-being and your success. On behalf of all of us, be safe.”

Like other companies in the industry ‘open for 大象传媒’, Plasmatreat has implemented certain actions, according to Grewal, including:

• Their labs and contract services remain open with a limited staff to safely support infrastructure critical sectors.

• They have made significant inventory investments (equipment and spare parts) to support customers during a time of supply chain concerns.

• Most of the company’s teams now work remotely and are available via phone, text, email or video conference. For general inquiries, email infoptna@plasmatreat.com.

• Their technical experts are available to support customers as well as to answer any questions related to plasma technology, materials treated, new projects and applications. To schedule a meeting, visit .

• They are also able to dispatch resources for infrastructure critical project support under mutually agreed upon, safe conditions.

Related Content

-

End-to-End Quality Management For Aseptic PET Beverage Bottling

Sidel introduces Qual-IS comprehensive quality system to merge all QC activities in PET aseptic beverage bottling, from the preform blowing to laboratory management.

-

Advanced Inspection of Bottles and Labels

NPE2024: Intravis shows new system for full label inspection on round, randomly oriented bottles; and redesigned bottle inspection system with more modular design.

-

New Concept for HDPE Paint Pails With Plasma Coating, Digital Printing

NPE2024: Delta Engineering presented integrated systems for injection molding, barrier coating and printing HDPE paint pails.