My Top Three Prizes for Most Irritating Plastic Packaging

More than most consumers, I feel really let down when plastic packaging isn’t user-friendly. Unlike most frustrated consumers, I can diagnose pretty well what went wrong in manufacturing or design of the failed product.

I hate it when this happens. Microwaving prepared foods in a black PP tray with a clear PET snap-on lid. Whoops. Gotcha! (Photo: Matthew Naitove)

Since my day job is helping manufacturers make better plastics products, it stings all the more when I encounter such products in my own home that make life not easier, but more difficult. Since I’m no ordinary consumer, I often can get a pretty good idea of what was overlooked in manufacturing or design of the product that is causing unnecessary frustration.

Here are my current nominees for Top Three Most Frustrating Household Plastics Products:

First Prize: Bags that won’t open (1). Small, white trash-bucket liners distributed by a national pharmacy chain. Packed individually in a box with nothing on the label indicating that they were manufactured outside the U.S. Take one out of the box, and the welded end and the openable end are visually indistinguishable. After a few minutes’ fussing with both ends of the bag, it becomes apparent that the “open” end is, in fact, ever-so-slightly welded, so it takes some vigorous rubbing to get an opening started, which then can be easily pulled apart. I put the blame on the bag maker here.

Second Prize: Bags that won’t open (2). Gallon-size, clear bags on a roll for fresh produce at grocery stores in my NYC neighborhood. Don’t know where they’re made. Cleverly folded so they fit on a very narrow roll. Dispenser makes it easy to tear them apart, but after that, the term “easy” doesn’t apply. My diagnosis is that high level of slip agent makes it more difficult than it ought to be to unfold the bag and get it open so I can put lemons or apples or whatever inside. I realize that slightly wetting my fingertips might help, but I don’t care to lick my fingers after handling products in a store, nor do I think spitting on my fingers would be well regarded by other shoppers (masked or not). So I rub and rub the slippery bag between my fingers until I get it open. Go easier on the slip agent, please!

Third Prize: Microwave messes. This strikes me as design rather than manufacturing malfeasance. When I buy prepared foods at a local deli or grocery story, it often comes in a black plastic tray with a snap-on clear plastic lid. Looks perfect for heating to serve. But there’s the trick on the unsuspecting consumer. The black tray is microwavable polypropylene—no problem there. But the sparkling clear plastic top, however attractive, is made of non-microwavable thermoformed PET. The result is similar to what is pictured here—a lid that has relaxed its formed-in stresses and collapsed in a misshapen blob onto the food contents in the tray. I hate it when that happens. Sometimes I’ve been lucky, when the black PP tray comes from the store with a translucent PP cover. That one goes in the dishwasher and then into my cookware storage cabinet.

If you have your own pet peeves about plastics products in the home not performing as they should, feel free to email me at mnaitove@ptonline.com. Tasteful photos welcome.

Related Content

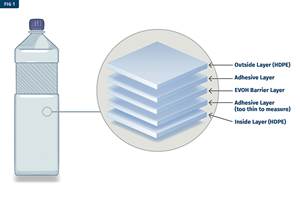

Measuring Multilayer Plastic Containers Made Easier With Today's Ultrasonic Gauges

Ultrasonic gauge technology has evolved to simplify measurement of very thin layers in plastic containers. Today’s gauges with high-frequency capabilities and specialized software can make multilayer container measurement quick and easy for ordinary users.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreRead Next

Ban ‘Single-Use’ Plastics? What If They’re Not ‘Single’ Use?

Today’s high-quality bowls and trays for deli foods and restaurant carry-out should not be branded with the despised “single-use” label.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More