More Servohydraulic Presses Debut at Fakuma

Wittmann Battenfeld completes its line with three new models.

After last year's Fakuma show in Germany, I wrote that the addition of electric servo motors to hydraulic pumps would be the salvation of hydraulic injection presses and ensure their continuing presence in the market for the foreseeable future. A sign of the trend was a number of new servohydraulic models at last year's show, including the new SmartPower line from (U.S. office in Torrington, Conn.).

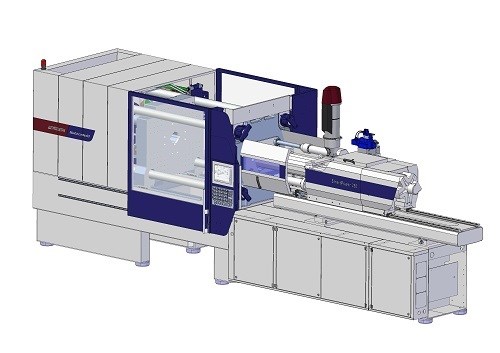

At this year's Fakuma show next month in Friedrichshafen, Wittmann Battenfeld will complete the line, which initially ranged from 25 to 120 metric tons, with three larger models of 180, 240, and 350 m.t., the last of which (pictured) will make its debut. It comes with tiebar spacing of 800 x 720 mm. All SmartPower models feature braking energy recovery for barrel heating. (For more Fakuma news, see our October issue's Keeping Up section.)

Related Content

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

-

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.