Let a Cobot Hand You a Beer

So-called ÔÇťcollaborativeÔÇŁ robots (or ÔÇťcobotsÔÇŁ) are supposed to be safe and easy to get along withÔÇöno need to wall them off in their own guarded areas.

Share

So-called “collaborative” robots (or “cobots”) are supposed to be safe and easy to get along with—no need to wall them off in their own guarded areas.

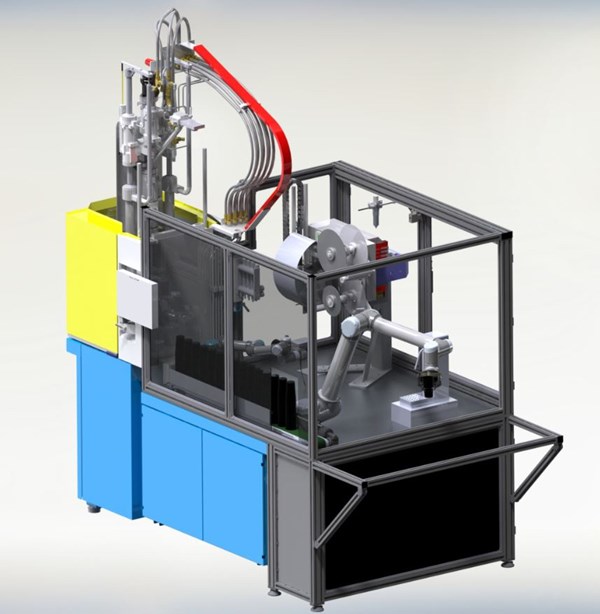

Just how easygoing cobots can be will be given new meaning at this month’s K 2016 show in Dusseldorf, at the exhibit of Dr. Boy GmbH & Co., German parent of Boy Machines Inc., Exton, Pa. A vertical Boy 35 EVV press will mold, label, fill, and serve beer glasses with the help of two obliging cobots from Universal Robots USA, Inc. (UR) of Denmark (U.S. office in E. Setauket, N.Y.).

One six-axis, articulated UR cobot will demold the glasses (something you probably haven’t seen one of these cobots do before) and place them in a labeling station to receive one of seven different images. A second UR cobot then places the glasses on a conveyor belt—empty—for visitors to take with them.

If you’re not satisfied with an empty beer glass, open a page on your smartphone using a QR code on the Boy press and enter your data into an input screen. The first UR cobot then receives the command to label a glass with a QR code containing your specific data. The second QR cobot then takes that specific glass from the internal transfer station and fills it with beer. You are then offered the filled glass, which you can easily take directly from the cobot’s gripper in a transfer area with no safety fence. How’s that for friendly?

(Note: the QR code on your glass also contains a variety of production data that can be retrieved from the Boy database.)

Related Content

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

-

Conair: Going All In on AI

Conveying with Optimizer, Conair’s new AI-based conveying technology stands to be a true game changer for plastics processors.