Free Webinar on Plasma LSR Adhesion for Medical Devices

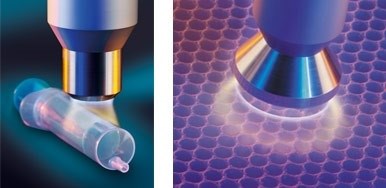

Plasmatreat's webinar addresses new LSR adhesion challenges for medical devices.

Liquid silicone rubbers (LSRs) have long been used in medical device manufacturing, since nearly every grade of LSR is biocompatible and available grades are specifically developed and approved for implants and similar medical applications. However, new high-performance substrates in combination with new two-shot injection molding techniques make adhesion of LSRs challenging.

According to Jeff Leighty, medical marketing manager for“Plasma helps overcome challenges stemming from both contamination of the substrate and from the inert substrate surface chemistry itself. Plasma opens the door for medical device manufacturers to design parts from a wider range of materials while reducing the risks of adhesion failure.”

Leighty explains how plasma improves LSR adhesion for medical devices in a free webinar offered by Plasmatreat that can been viewed at .

Related Content

-

High-Throughput, Robust Thermoformer

NPE2024: WM Thermoforming’s new generation of FC1000 IM2 offers the highest throughput per square feet.

-

Low-Smoke, Non-Halogen Polyolefinic Compound for Armored Cables

Avient’s latest addition to its ECCOH portfolio is designed to prevent environmental stress cracking in low- and medium-voltage cable sheathing.

-

Measuring Technology Specialist Pixargus Acquired by CiTex Group

A global player in optical inline quality control, Pixargus is intensifying presence in U.S. & Asia under CiTex umbrella.