First High-Barrier PLA-Based Flexible Film for Long Shelf-Life Pouches

Italian film processor combines coating technology with NatureWorks Ingeo films for packaging of processed foods.

Italian film processor combines coating technology with NatureWorks Ingeo films for packaging of processed foods.

Used successfully for several years in fresh food packaging, Ingeo PLA from , Minetonka, Minn., has now been used in the first application for use in shelf-stable food packaging, with the focus on the long shelf-life pouch market.

Italy’s Metalvuoto, an over 45-yr old processor of metalized plastic films for food packaging and for the consumer electronics market, combined its Oxaqua, high-barrier PET film coating technology with Ingeo PLA to produce dual-function films that enable simplified flexible packaging structures—such as flat, stand-up, or squared-bottomed pouches.

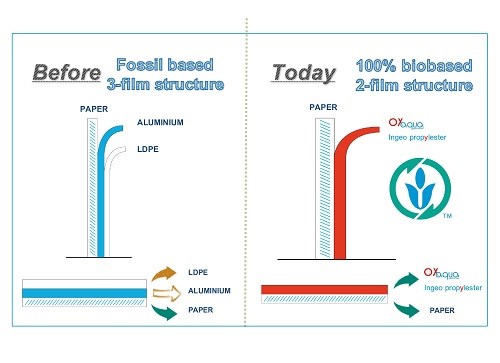

Branded Ingeo Propylester, the new Metalvuoto film allows using a two-layer pouch with performance matching that of three-layer pouches. Says the company’s executive director Gianni Costanzo, “Until now, the flexible packaging industry has grown up around the use of multi-material laminates because no one material was able to provide multiple functionality. For example, brand owners often use an aluminum layer for barrier, a PET layer for external aesthetics, and an internal PE layer for heat-sealability. Now, we have used our Oxaqua coating technology with an Ingeo base film to replace two layers of different materials with one layer that simultaneously provides excellent barrier and heat sealability.”

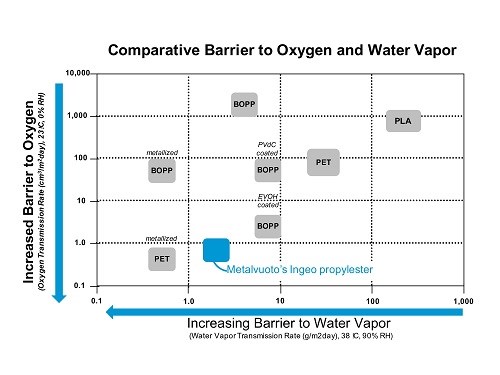

Ingeo Propylester film has significantly better oxygen barrier than metalized BOPP, according to Metalvuoto. (Barrier performance is compared in the figure shown here against a range of materials normally considered for use in flexible packaging markets.)

Moreover, because the new films provides good seal strength, it eliminates the need for an additional sealant layer and enables a structural package simplification.

According to Constanzo, the company expects strong interest from the market in two-layer structures in which the Ingeo and Oxaqua biocoating technology are combined with paper to provide a fully biobased performance package at a cost that is competitive with three-layer structures.

The new film is well suited for food packaging in both horizontal and vertical form-fill-seal applications, and has demonstrated good processability. In testing on pouch-making machines, 30 to 40 units per minute were produced, depending on the type of Forest Stewardship Council (FSC) certified paper pouch—flat, stand-up, or square-bottomed.

Search for nearly 100,000 grades of polymers on the Universal Selector by clicking here

Related Content

-

Single vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

-

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

-

How To Identify Resin Degradation in Single-Screw Extruders

Degradation can occur in many single-screw extrusion operations, and typically occurs due to minor design flaws in the screw. Here is how to track it down.