"First" Bacteria to Upcycle Single-Use PET Heading to Space

Collaborators at Seed Health, MIT, NREL, Weil Cornell and Harvard have built an autonomous biological system which converts PET to an environmentally-benign “new” plastic.

We have reported over the last several years on bacteria-based biodegrable bioplastics with PHA (polyhydroxyalkanoate) the most notable in terms of commercial realization and impact. Recently, we were contacted by , a microbiome science company, regarding its new environmental research collaboration with , the , and , which will send the first bacteria to upcycle single-use plastic (PET) to the International Space Station (ISS). At the helm, is Seed Health’s environmental division SeedLabs which harnesses the power of microbes to unlock a new method for the degradation, reuse and redesign of plastic that could reimagine the future of waste management—both in spaceflight and on Earth.

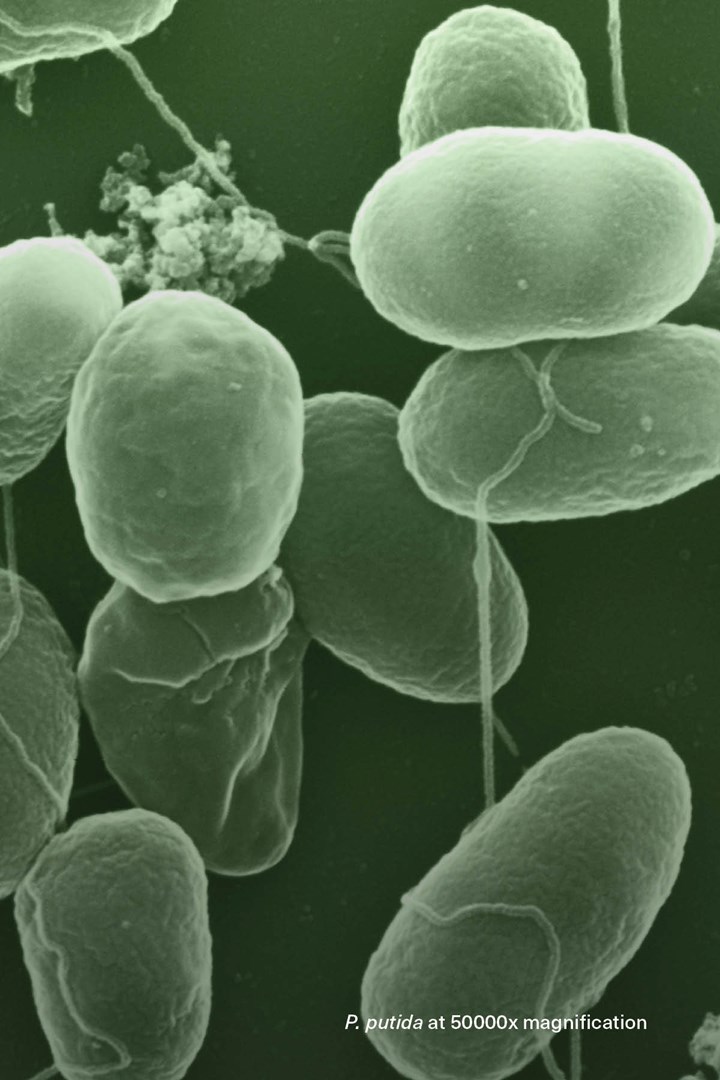

Collectively, this project’s team have built the first biological system to upcycle single-use PET into an environmentally-benign ‘new plastic’ via engineered bacteria. The system first introduces PET to a specialized enzyme, which breaks it down into organic compounds, then utilizes the bacterial strain Pseudomonas putida to convert these compounds into β-ketoadipic acid (BKA)—a high-performance nylon monomer which can be formulated into various objects.

The biological system was scheduled for transport to the ISS aboard SpaceX CRS-26 on November 26, 2022, out of Kennedy Space Center. The unique microgravity and radiation at the space station may act as catalysts for sustained, enhanced bioactivity, allowing for more efficient biological upcycling. Moreover, the conditions will allow the researchers to test mechanistic performance following exposure to UV radiation outside of Earth’s atmosphere, in anticipation for changing environmental conditions on Earth and beyond. Once in-orbit, the autonomous system will proceed with the pre-programmed experiment schedule, enabling culturing and data collection without need for human intervention or astronaut resources.

Said NREL biologist Allison Werner, “Microbes have evolved enzymes and catabolic pathways to degrade and catabolize human-made plastics as carbon and energy sources. Our system takes that biological process one step further, microbially upcycling those degraded compounds into a high-performance material for reconfiguration. This empowers us to not only redefine the lifetime of synthetic plastics on Earth, but represents a new frontier for resource utilization in space travel.”

Explained Xin Liu, MIT Space Exploration Initiative Arts Curator, “Microbes’ versatile upcycling capabilities offer a promising tool for the future of space exploration, where In-situ Resource Utilization is crucial for longer and more adaptable manned space missions. We hope our open-source system can present a potential to enable more access to synthetic biology experiments and applications in spaceflight that will ultimately enable resource-sustainability in space travel. More importantly, we must remember that our Earth is also a spaceship –– for us, the importance of this research is not limited to space flight but its benefit for our home planet."

Seed Health Co-CEO and Co-Founder, Raja Dhir, noted that the company was founded on the belief that the application of microbes holds vast potential to solve some of our greatest health and environmental challenges. “It is an honor to collaborate with experts at the forefront of microbial innovation to empower a circular economy for plastic and to imagine a future where ecologies impacted by human activity could recover.” This latest expedition expands Seed Health’s environmental work under SeedLabs, reflecting its commitment to advance microbially-derived solutions for planetary health. Existing SeedLabs initiatives include the development of probiotic innovations for honeybee preservation and coral reef regeneration.

Related Content

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More