Fine-Particle Cellulosics Key To Patented Bio-Plastic Compounds

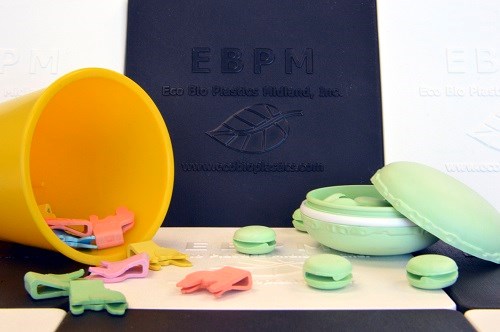

Through a Japanese/U.S. joint venture, a new range of customized bio-plastic compounds are now available in North America.

Within the last two years, Midland, Inc., (EBPM), Midland, Mich., has been leading the way in the use of a novel new method in which cellulosic material and post-industrial waste paper can be used to create bio-plastic products.

The patented technology originated at the Tokyo-based Eco Research Institute (ERI), one of Asia’s biggest bio-plastics manufacturers. A subsequent joint venture with the Michigan Molecular Institute, a global leader in advancing polymer research, has allowed for the “earth-friendly” composite resin, called MAPKA, to be made available to North American’s processors, with EBPM and ERI holding the exclusive technology.

MAPKA bio-plastic or bio-plastic content compounds can be based on such virgin or recycled materials as PP, LDPE, HDPE, ABS, EVA as well as PLA and PHA. They are created by dry-grinding various types of cellulose down to the mean particle size of 20 microns, and incorporating the filler into the plastics. According to the company, the cellulosic fillers can comprise up to 65% of the total weight of the product, enhancing the plastics physical and mechanical properties while remaining virtually undetectable to the naked eye.

While incorporation of cellulosic material into plastics in not new, EBPM’s patented pulverization technology reportedly allows for the production of significantly more enhanced compounds of this type. “When you compound plastic with organic material, you need that material to be a very fine powder. We are the only manufacturer in the world with the ability to do that on a large, commercially viable scale,” explains EBPM’s v.p. Fukuji Saotome.

EBPM serves a broad variety of industries looking to reduce their reliance on unsustainable materials. The company can customize the compounds to fit specific property requirements and applications, ranging from housewares and consumer goods to building products and automotive components. Moreover, EBPM enables “closed-loop recycling systems” for companies with their own scrap paper materials.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastic Technology’s Plaspec Global materials database.

Related Content

-

Part 3: The World of Molding Thermosets

Thermosets were the prevalent material in the early history of plastics, but were soon overtaken by thermoplastics in injection molding applications.

-

Prices of All Five Commodity Plastics On the Way Up

Despite earlier anticipated rollover in prices for most of the volume commodity resins, prices were generally on the way up for all going into the third month of first quarter.

-

Prices for PE, PS, PVC, PET Trending Flat; PP to Drop

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.