Expanding Production Bumps Index Above 50

Index expands for first time since June 2019.

The Plastics Processing Index expanded for the first time since June 2019 with a February 2020 reading of 51.8. (Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The farther away a reading is from 50, the greater the change in activity as compared with the prior month.)

Most of the Index’s components reported improved figures versus the prior month. review of the underlying Index reveals that the Index—calculated as an average of its components—was supported by an eight-month high in production activity and a modest expansion in employment. The Index was pulled lower by a sharp contraction in export activity and a ninth consecutive month of contracting backlog activity.

​​FIG 1 Both indexes expanded in February for the first time since June 2019. Plastics processors reported expanding production, new orders, supplier deliveries and employment activity. This positive news, however, will likely be soon overshadowed by COVID-19’s mounting impact on the global economy.

​​FIG 1 Both indexes expanded in February for the first time since June 2019. Plastics processors reported expanding production, new orders, supplier deliveries and employment activity. This positive news, however, will likely be soon overshadowed by COVID-19’s mounting impact on the global economy.

Manufacturing Outlook as a Result of Coronavirus

The impact of COVID-19, widely known as the Coronavirus, is expected to have an adverse effect on the Index in the coming months. The necessary efforts of Asian governments in January and February—and by a widening collection of nations in February and March—to combat the spread of COVID-19 are also having a detrimental impact on the world’s supply chain, as workers, companies and cities are affected by quarantine measures. This will most immediately restrict the normal flow of upstream and sub-component goods which are necessary for the proper functioning of the manufacturing sector.

Both the overall Plastics Processing and Custom Processor Indexes are unique in their ability to measureNorth American ґуПуґ«ГЅ conditions on a monthly basis. This means that moving forward these indexes will be able to quantify both the initial shock from the virus along with the timing and strength of the market’s eventual recovery from the economic impact of the virus.

​​​​​​​FIG 2 Gardner Intelligence expects that most—if if not all—of its indicators will be subjected to shocks from COVID-19. That the virus originated in Asia suggests that American manufacturers in the immediate future should pay particular attention to their supply chains and expect increased volatility in export orders and material prices.​​​​​​​

​​​​​​​FIG 2 Gardner Intelligence expects that most—if if not all—of its indicators will be subjected to shocks from COVID-19. That the virus originated in Asia suggests that American manufacturers in the immediate future should pay particular attention to their supply chains and expect increased volatility in export orders and material prices.​​​​​​​

As the Index is based on responses to surveys conducted each month by subscribers to Plastics Technology magazine, it is particularly important at this time for our subscribers to complete the GBI survey sent to them each month. Your participation will enable the best and most accurate reporting of the true magnitude and duration of COVID-19. It will allow you and your peers to make data-driven decisions at a time when there may be a strong temptation to make impulsive gut-decisions that could make a difficult situation worse.

ABOUT THE AUTHOR: Michael Guckes is chief economist and director of analytics for Gardner Intelligence, a division of Gardner Business Media, Cincinnati. He has performed economic analysis, modeling, and forecasting work for more than 20 years among a wide range of industries. He received his BA in political science and economics from Kenyon College and his MBA from Ohio State University. Contact: (513) 527-8800; mguckes@gardnerweb.com. Learn more about the Plastics Processing Index at .

Related Content

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

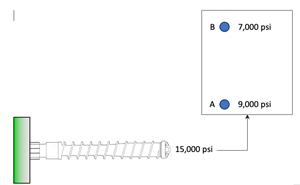

Read MoreUnderstanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More.jpg;width=70;height=70;mode=crop)