CJ Bio’s Amorphous PHA Demonstrates Excellent Biodegradability in Marine environment

The tests of the bioplastic, a semi-crystalline PHA and a PLA were conducted by the national Korean testing agency (KCL)

In early May, I reported on the development of Phact Marine Biodegradable Polymers based on a proprietary amorphous PHA technology from of Woburn, Mass., a division of South Korea-based CJ CheilJedang. Currently, this is said to be the only amorphous PHA on the market. Amorphous PHA is a softer, more rubbery version of PHA that offers fundamentally different performance characteristics than the crystalline or semi-crystalline forms that currently dominate the PHA market.

For its initial applications, Phact A1000P is being targeted as a modifier to other compostable polymers and biopolymers to improve functional and processing characteristics, and for enabling these products to achieve faster rates of biodegradation or composting. Then, in mid-May, I reported on a letter of intent that established a strategic alignment between CJ Bio and leading producer of PLA NatureWorks. The companies plan to work together to develop sustainable materials based on Phact marine biodegradable PHA bioplastic and Ingeo PLA bioplastic. Their goal is to develop high-performance biopolymers that will replace fossil fuel-based plastics in applications ranging from compostable food packaging and food serviceware to personal care, and beyond.

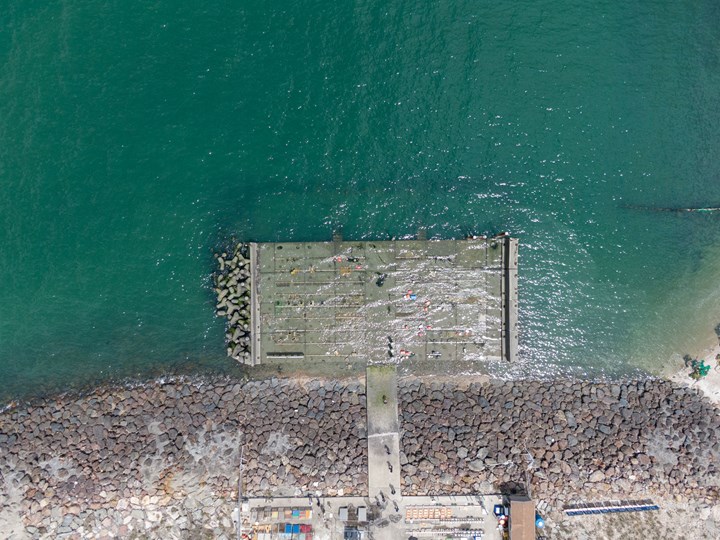

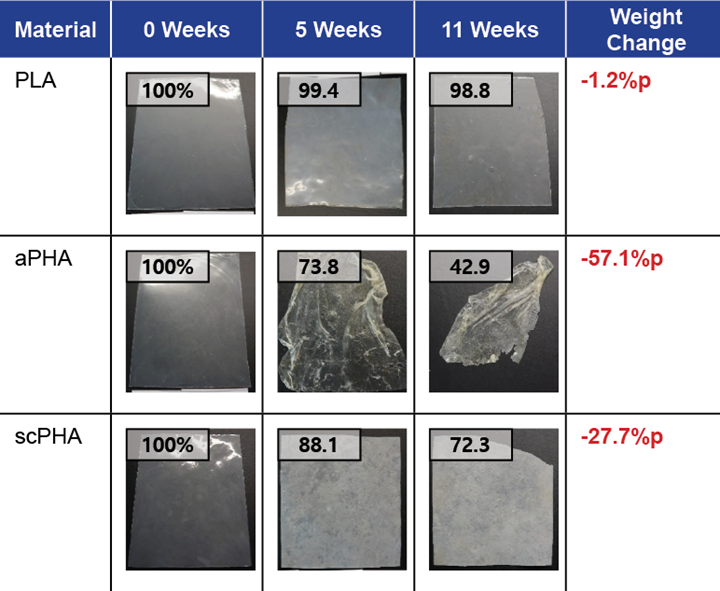

We were recently alerted by CJ Bio that the company’s Phact amorphous PHA was tested by the Korea Conformity Laboratories (KCL) and the results are very promising. KCL placed CJ Bio’s amorphous PHA, along with semi-crystalline PHA, and PLA films (the size of A4 paper) into Korea’s West Sea and measured the weight changes at intervals of two weeks for 11 weeks. While 57% weight loss was recorded for the amorphous PHA, the weight of the semicrystalline PHA declined 28%, and PLA lost 1.2% of its weight.

Said Seung Jin Lee, Head of the Biomaterials 大象传媒, "KCL's experiments in the Western Sea Coast are important because they have proven PHA's excellent biodegradability and industrial value outside of the lab and in real-world conditions. We expect that mixing our amorphous PHA with other materials, such as PLA and PBAT, will improve the levels of biodegradability in those polymers, and we are continuing to conduct research and development with those materials and others.”

CJ BIO is the world’s first and only producer of amorphous PHA, which is TUV OK Certified for industrial and home compost, soil biodegradable, and marine biodegradable. It is considered ‘home compostable,’ meaning that it does not require specialized equipment or elevated temperatures to fully degrade. CJ BIO is continuing to analyze the biodegradable properties of PHA in collaboration with KCL. Marine biodegradation experiments on products including packaging and straws made from a mixture of PHA and other biodegradable materials were started over the past month, and the impact on the ecosystem is also being measured.

Meanwhile, production of amorphous PHA has started at CJ Bio’s manufacturing facility in Pasuruan, Indonesia, which has a rated annual capacity of 11 million lbs, with plans to increase production to meet expected demand.

South Korea is ranked second among the highest recyclers of municipal solid trash among countries that are part of the Organization for Economic Cooperation and Development (OECD), with recycling composite rates of around 60%. KCL is a government-designated national supplier organization that tests, evaluates and certifies products and services in the fields of construction, living, and the environment. The Korean Ministry of Industry, Trade and Resources organized the testing through KCL to further the government’s efforts to investigate technologies that can help the Asian nation to continually improve the health of the global environment and to reduce its global footprint.

Related Content

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

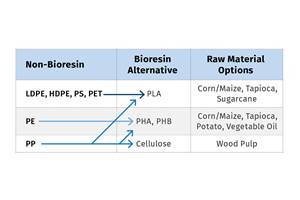

Read MoreHow to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

Read MoreNPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More