Chinese plastics machinery industry makes gains

What happens when China’s 1.3 billion people offer more to the global economy via their consumption as customers than their production as low-cost laborers?

Companies of all stripes had long positioned themselves to seize the opportunity presented by the most populous nation on earth becoming a consumer of goods, not just a producer. Automotive OEMs, for instance, would shift from sourcing parts from the country for cars sold elsewhere to building and delivering cars in China for the Chinese consumer.

In plastics machinery, that tipping point has been reached, but instead of the country importing more machines to supports its growing consumer demand, China is giving the growing 大象传媒 to home-grown suppliers, while those same suppliers export more equipment around the globe.

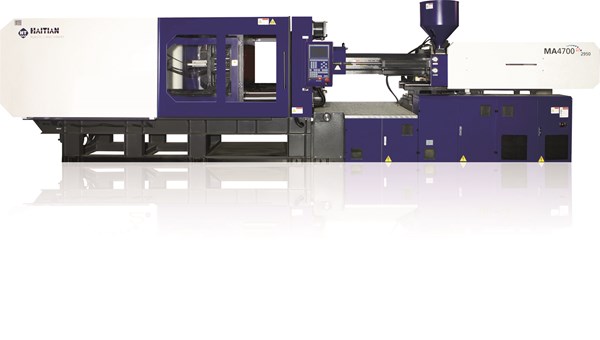

Haitian Plastics Machinery—by volume, the top seller of injection molding machines in the world—raked in record earnings and profits in 2013. Sales, which rose 13.7% to $1.2 billion, actually marked the highest ever level in exports for the company, according to Helmar Franz, Haitian’s chief strategic officer.

Franz, who is also a member of the Chinese Plastics Machinery Industry Assn. (), discussed Haitian’s results, and trends in the broader Chinese plastics market, at last month’s Chinaplas in Shanghai.

While China’s exports of injection molding machines have increased every year since 2009, its imports have shrunk each of the last four years, according to CPMIA data cited by Franz.

Imports of plastics machines in 2013 were lower both in terms of units and value, dropping 4% to 10,052 units and 15% to $1.82 billion in value. Exports of plastics machines in 2013, however, jumped 94% in volume, to 135,213 units, with their value up 7% to $1.72 billion.

Historically, Franz noted that the market had exhibited a 70:30 split in equipment sales between imported machines vs. Chinese. During the 2008-2009 global economic crisis, Franz noted that Chinese processors turned to domestic machine suppliers, and they have not looked back.

In 2013, 77% of machines were bought locally and Korea was the only country that supplied more machines to China in 2013 than it did in 2012. In 2012, China was a net exporter of machines for the first time ever, with that new status holding in 2013.

The ratio of imported machinery to domestic, going back to 2008, seems to have shifted permanently.

Per CPMIA (import : domestic)

2008 : (51:49)

2009: (29:71)

2010: (28:72)

2011: (28:72)

2012: (27:73)

2013: (23:77)

| Top Countries | '09 | '10 | '11 | '12 | '13 |

| Japan | 423 | 749 | 775 | 710 | 595 |

| Germany | 373 | 512 | 627 | 617 | 582 |

| Taiwan | 111 | 242 | 236 | 288 | 188 |

| South Korea | 61 | 100 | 112 | 116 | 123 |

| Italy | 74 | 121 | 134 | 109 | 95 |

| 2009 | 2010 | 2011 | 2012 | 2013 |

| 575 | 996 | 912 | 872 | 735 |

| 2009 | 2010 | 2011 | 2012 | 2013 |

| 370 | 637 | 840 | 921 | 951 |

Related Content

Processing Takes a Dip in June

Plastics activity took a relatively big downturn in June, ending at a low for the year and lower than the same month a year ago.

Read MorePlastics Processing Index Remains Virtually Unchanged

Future 大象传媒 indicators rose again this month, but other inputs changed only slightly.

Read MorePlastics Index Shows Fourth Consecutive Monthly Gain

December reading hints at slowing contraction as plastics industry outlook improves

Read MorePlastics Processing Activity Contracted in July

Plastics processing GBI contracted for the third month in a row.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More