With This New Process, You Can't Be Too Thin or Too Fast

Minneapolis custom molder Midwest Plastics Components (MPC) hopes that helping to pioneer a novel high-speed injection molding concept will give it a leg up in the emerging micro-molding market for precision thin-wall parts that weigh less than a gram.

Minneapolis custom molder Midwest Plastics Components (MPC) hopes that helping to pioneer a novel high-speed injection molding concept will give it a leg up in the emerging micro-molding market for precision thin-wall parts that weigh less than a gram. MPC is the first molder in North America to make commercial use of X-Melt, a process developed in 2001 by machine builder Engel Austria GmbH.

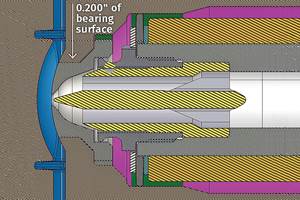

It eliminates the need for a gas accumulator to achieve super-high-speed injection. Instead, X-Melt exploits the natural elasticity of plastic melts. It uses the screw and a shutoff nozzle to pressurize the melt to a very high but defined level in the machine barrel. When the valve is opened, the compressed melt expands in the cavity at an explosive rate, even faster than can be achieved with an accumulator. In effect, X-Melt uses the energy stored in the pressurized melt to fill the mold without moving the injection ram. X-Melt reportedly uses one-third to half as much energy to fill the mold and simplifies the process by eliminating the need to determine injection-speed and holding-pressure profiles.

MPC employs this technology to attack a niche market for tiny surgical implant devices used in vascular, ocular, facial, and nerve-regeneration applications, as well as devices that aid in reattachment of a ligament or tendon to a joint. MPC uses special polyester resins to mold resorbable devices. “With X-Melt, we make long, thin, flexible products that allow for smaller incision sites and can compete with sutures. We can injection mold products that previously had to be extruded or did not exist,” says Dale Gildemeister, MPC project engineer.

“We haven’t found a limit to how thin we can go yet,” says Gildemeister. “We have molded a tube 22 mm long with a 0.25-mm wall thickness. We are looking at thinning that same tube down to a 0.07-mm wall,” he adds. MPC has found X-Melt effective for parts weighing 4 g or less.

All-electric precision

MPC began in the 1960s under the name McCourtney. Today, it operates 47 injection presses from 17 to 700 tons to serve automotive, defense, industrial, and medical markets. MPC has four clean rooms of class 100,000 and class 10,000.

MPC uses X-Melt on a 60-ton Engel E-Motion all-electric press fitted with a special screw, barrel, hot-runner system, and shut-off nozzle that are all able to withstand pressures up to 54,000 psi. It also features adaptive software that minimizes variation in the locking behavior of the non-return valve. The press was supplied by Engel Canada, Guelph, Ont., and the hot-runner system and shutoff valve were designed in cooperation with Mold-Masters Ltd., Georgetown, Ont.

Engel says the X-Melt process requires its E-Motion line of all-electric machines, due to the critical requirement for controlling screw position, which helps control the pressure applied to the melt. The system reportedly can deliver parts with weight variation as tight as ±0.03%, which compares with ±7% achieved with accumulator injection.

This is where MPC is looking to gain its edge in medical molding. “With X-Melt, the standard deviation in cavity pressure over 100 shots is just 13 psi,” says Gildemeister. “We are making a shift in our strategy from trying to achieve machine repeatability to achieving polymer repeatability.”

MPC has four thin-wall applications for X-Melt. Mold fill times are no more than 1.5 millisec. It takes some trial and error to determine the correct pre-compression position and the operating profile of the shutoff valve, says Gildemeister.

Using X-Melt, MPC can consistently produce parts from 0.4 to 0.8 g with wall thickness down to 0.1 mm. “We have made parts down to 4 g with other methods, but not thin-walled parts. We could achieve a 0.6-mm wall using special flow enhancers in the cavity, but the enhancers could generate material waste, which is expensive when the polymer costs several thousand dollars per kilo,” Gildemeister says.

Related Content

RFID Applied to Hot Runner Systems

Hasco says the adapted variant of the Mold Tag makes it possible to read out all data on the hot half or a wired system directly on a smartphone.

Read MoreConstruction Begins on Fully Automated Hot Runner Production Plant

Oerlikon HRSflow will start the construction of a new fully automated plant in San Polo di Piave, Italy, to expand capacity for the growing European market.

Read More3D Printed Hot Runner Nozzles, Pressure Pads Provide Reliable Temperature Handling

NPE2024: Witosa GmbH, through its distributor DMS, brings the Monolith hot runner nozzle and hardened steel Energy Blocker to the U.S., enabling the reduction in time, costs and improvements in product quality.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More