Will You Be Ready for the Next Disruption?

Lessons learned from ongoing coronavirus pandemic should help ┤¾¤¾┤½├¢ navigate through the next disruption.

It happened that fast. Like a push of a button, a flick of a light switch or a bolt of lightning. The COVID-19 pandemic hit our shores and spread to dramatically impact our personal and professional lives. Our essential industry—up and down the supply chain, from materials to presses to tooling to auxiliary equipment to processors themselves—was among those that responded heroically, ramping up production to meet needs not only for PPE, but for everyday products used for packaging that were suddenly and almost literally flying off grocery store shelves.

We covered a lot of these yeoman efforts here in the print magazine and on our website. They include stories of companies adding machines, changing the configuration of existing machines to make products they never would have imagined possible before, and in some cases laying the foundation to expand into altogether new ┤¾¤¾┤½├¢ as a result of new opportunities.

In this space last month, I talked about how we’ll be addressing these themes in the upcoming months, either in print, online, or both. We kicked off this coverage this issue with an article on digital manufacturing, p. 28. (When you’ve finished reading it, visit the Plastics Technology website, ptonline.com, for additional reporting on how a processor a molder utilized a recently installed ERP system to ramp up production of sanitizer bottles by 4.3 million in just three months.) Next month, we’ll examine advanced automation, then additive manufacturing (though the lens of an injection molder that has added 3D printing capacity for production), cross-training, reshoring, and among other topics.

I know that these topics are not altogether new to you, but my suspicion is that you will be looking at them more carefully as part of a ┤¾¤¾┤½├¢ and technology strategy that you’ve likely revisited many times since the emergence of COVID-19, and we want to help jump start you through the process.

Switching to a more robust domestic supply chain and employing advanced manufacturing technologies could reduce the dependence on the increasingly fractured global supply system.

Speaking of which, I’d like to make you aware of two additional resources that you might find useful. This summer, the Association for Manufacturing Excellence (AME, ame.org) released a white paper, A Manufacturing Marshall Plan, that maps out exactly how today’s companies can prevent post-pandemic supply-chain disruptions, advance their manufacturing productivity and reskill their workforces.

Said AME, “A Manufacturing Marshall Plan advocates for reshoring, nearshoring and LeanShoring [a term AME trademarked] together with an increased focus on Industry 4.0 innovations and enhance educational and training offerings to create a stronger workforce. These three actions will provide companies and their communities with a distinct competitive advantage while also boosting productivity and improving sustainable resilience in a fast-changing competitive manufacturing world.”

According to the white paper, the coronavirus pandemic is taxing the efficiency and cost benefits of a globalized supply-chain system. And it recommends a switch to a more robust domestic supply chain and advanced manufacturing base, which could reduce dependence on the increasingly fractured global supply system.

You can download the white paper by visiting short.ptonline.com/AMEpaper.

More recently, I received a report from quick-turn, “digital manufacturing” specialist ProtoLabs, based on a survey of its customers. The report, Product Development, and the Supply Chain: How to Survive a Pandemic with Digital Manufacturing, reveals how the pandemic exposed supply-chain deficiencies—challenges that many customers say were mitigated by embracing additive manufacturing technology. Visit the ProtoLabs’ website (protolabs.com) for more on this study.

Related Content

American Injection Molding Institute Opens Mold Maintenance Classroom

The Beaumont subsidiary has opened the Mold Maintenance Center of Excellence classroom at its Erie, Pennsylvania, headquarters.

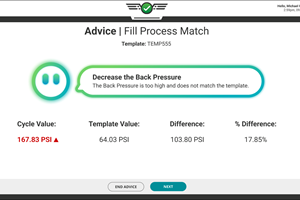

Read MoreSmart Assistant Bridges Injection Molding Skills Gap

NPE2024: MAX the Process Advisor, as well as free presentations and training by RJG Inc.

Read MoreThe Cost of High Employee Turnover in Injection Molding: Why Retention Matters

Starting in molding in 1993 and clocking in for nearly every job on the floor over the intervening decades, I’ve seen all sides of the hiring, training and retention process in the industry. Here are my thoughts on how to keep your most important asset — your people.

Read MoreOpen Press/No Operator: Plastics Processing and the Skills Gap

Order for parts? Check. Material…machine…mold? Check…check…check. Operator? Operator…?

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More