TP Composites: New Option in Lightweight PP/Glass Composites

From its Detroit-area offices, Swiss-based Quadrant Plastics Composites (QPC) has introduced a family of lightweight reinforced thermoplastic (LWRT) composites to North America.

From its Detroit-area offices, Swiss-based Quadrant Plastics Composites (QPC) has introduced a family of lightweight reinforced thermoplastic (LWRT) composites to North America. SymaLite LWRT sheets and precut blanks are high-loft, air-permeated composites made from a commingled fleece of polypropylene fiber and glass fiber. They are intended for use in large, semi-structural automotive and non-automotive panels.

Harri Dittmar, QPC’s composites market development manager, says the lower density of LWRT composites produces higher stiffness per unit weight than traditional glass-mat thermoplastic (GMT) sheet. It also provides potential weight reduction, extended design freedom, and cost advantages versus metals, GMT, and conventional long-fiber thermoplastic (LFT) compounds of PP and nylon. The first commercial success for SymaLite is an underbody shield assembly for BMW’s 2004 model 5 series of vehicles in Europe.

SymaLite is a new alternative to a lightweight GMT composite produced by Azdel Inc. and marketed by GE Plastics. Azdel SuperLite sheet is made from PP powder and chopped glass. It is widely used in automotive headliners, instrument panels, interior trim, and other applications.

Dittmar says SymaLite is suitable for automotive underbody shields, load floors, headliners, interior and door trim, parcel shelves, roof modules, hoods, and trunk lids. Other targets are recreational, agricultural, and construction vehicles plus sporting goods and building panels.

The new composite is friendly to in-mold decorating due to its low-pressure formability and its easy adhesion to textiles, scrim, foams, dry-paint films, and solid PP skins. With the addition of an adhesive film, SymaLite can also be bonded to coil-coated aluminum sheet. QPC is in the early stages of considering aluminum/plastic laminates for Class A automotive roof modules.

Novel production process

QPC’s lightweight version of GMT yields different properties than either classic GMT or Azdel’s lightweight GMT. Azdel SuperLite is made by a wet process adapted from paper-making that combines loose chopped-glass fiber with PP powder.

QPC uses a dry production method adapted from textile manufacturing to create a mixed PP and glass-fiber fleece, which is then needle-punched to tailor the properties for the application. In a continuous process, the fleece is heated above PP’s melting point, laminated to surface layers—e.g., adhesive films or unfilled PP skins—and cut into blanks. Long (78-mm) glass fibers are used to create a 3D matrix that resists the separation of resin from fiber that can occur when short chopped fiber is molded into a part. QPC claims there is full impregnation of glass by PP, as well as excellent control of lofting.

QPC has capacity in Germany to make sheet containing 20% to 60% glass, though currently available grades range from 40% and 55% glass. The 40% loading is suitable for underbody shields, load floors, and sunroofs. The stiffer, 55%-glass products are for headliners. Blanks are available in standard sizes of 22, 30, 45, and 90 in. and can be customized.

When heated, the sheet lofts, or expands, to five times its original thickness as the glass fibers attempt to unbend from their compressed state in the consolidated blank. Degree of lofting can be tailored by changing the glass content or the needling method used. Higher glass content results in increased lofting and lower density, translating into higher specific stiffness (stiffness-to-weight ratio) in finished parts.

QPC’s low-pressure “thermo-stamping” process converts blanks into parts. It uses matched aluminum molds that cost less and require less lead time than steel tools. The tool forms the part shape while imparting little or no flow to the material. The mold compresses the lofted sheet more deeply in some areas and less deeply in others: thicker sections have higher stiffness; thinner ones have less stiffness but higher tensile strength.

First commercial success

BMW’s underbody shield comprises four parts with 40% glass content. The composite sheet is laminated with unreinforced PP skins on both sides that increase impact, abrasion, and moisture resistance. The assembly replaces a conventional GMT version, providing a 30%, or 8.8-lb, weight saving. The composite also reportedly provides superior sound damping and reduced drag coefficient. The processor is Seeber AG, a tier-one supplier based in Mannheim, Germany, and having a plant in East Duncan, S.C.

Underbody-shield components are made in cycles of less than 60 sec using a family mold with cavities for all four parts of the assembly. Blanks of 79 x 73 in. are fed to the family mold, which incorporates a mechanism for cutting attachment holes into parts during forming.

BMW’s assembly takes advantage of the ability to vary thickness of the cross section without changing overall part weight or area weight throughout the part. The center areas of parts are 4 mm thick, optimizing specific stiffness and acoustic performance, while the perimeters are 1 mm thick, boosting attachment and seal strength.

QPC has initiated R&D aimed at using its composite for in-mold decorating of exterior body panels for automobiles and off-road vehicles. Current efforts are focused on adhesion of pre-painted aluminum skins to SymaLite LWRT cores for roof modules. Aluminum’s coefficient of linear thermal expansion (CLTE) is comparable to that of the composite, which reduces warpage risks. Coil-coated aluminum is also thin enough to offer weight savings. Work on adhering plastic dry-paint films to lightweight GMT cores is under way, too.

Related Content

Understanding the Effect of Pressure Losses on Injection Molded Parts

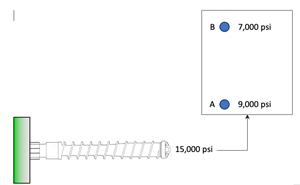

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Read MoreProcess Monitoring or Production Monitoring — Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More