Reborn HPM Launches New Injection & Extrusion Machinery

Much has changed in a year for HPM Corp., the 125-year-old Ohio manufacturer of injection, extrusion, and die-casting equipment.

Much has changed in a year for HPM Corp., the 125-year-old Ohio manufacturer of injection, extrusion, and die-casting equipment. After entering bankruptcy and losing almost all its staff last year, it has new ownership and new management, a newly restored workforce, and both new and upgraded products in its machinery lines.

All HPM's assets were purchased in July 2001 by Taylor's Industrial Services LLC of Hobart, Ind., a firm specializing in transporting large components and building mechanical stamping presses. The company has been debt-free since its purchase by Taylor's. Employee rolls have swelled from eight persons a year ago to more than 130 today, and hiring continues. HPM is now running two production shifts. The company is also expanding abroad with the opening of a new sales office in Beijing China, and the enlargement of the HPM sales group in Latin America. HPM will also be exhibiting at NPE 2003 in Chicago next June.

From brink to boom

According to new president and CEO Christopher Filos, "The combination of a tough economy and management issues led HPM Corp. to file for bankruptcy protection last year. The company's inherent strengths in quality and customer service were never in question, and they are still the foundation we are building HPM on." Filos, who is also the owner of Taylor's Industrial, says his company is the only one of its kind able to offer design and manufacturing of turnkey plastics processing systems, plus trucking, installation and servicing, all under one umbrella without outsourcing.

HPM has also revamped its machines. "We are making all HPM product lines and providing spare parts and services through our TSS (Taylor's Support Services) group," says Filos. Sales from the HPM division this year are projected to reach $40 million, and next year's forecast is $60 to $70 million, depending on the economy.

New machines to debut

HPM retains its historic role as a builder of fully hydraulic injection presses in larger tonnages and is expanding its product range with two new lines of smaller presses. HPM is rolling out a brand-new series of general-purpose toggle-clamp machines in 95, 165, and 285 tons. The new GP series comprises basic machines with no options. They start at $55,000. The GP series joins HPM's new mid-range FX series toggle presses designed for fast-cycle molding and sized from 99 to 660 tons. HPM also offers its high-end universal line of toggle presses, which span a range of 60 to 560 tons.

HPM will discontinue production of its Access series of tiebarless machines but will continue to service all such units in the field. Meanwhile, HPM is replacing its Next Wave line of two-platen hydromechanical presses with the new Freedom series. The Freedom series, available now, is sized from 600 to 5000 tons. Unlike the Next Wave line, it has Vickers variable-speed pumps that allow for overlapping process functions (e.g., clamp and screw movements).

HPM also offers its Modular series of three-platen hydraulic machines. They let users custom-build a press from a selection of reciprocating screw or accumulator injection systems and clamping systems from 220 to 4000 tons.

HPM designed new, more efficient controls or its GP series. The firm may extend the controls (manufactured by Siemens) as options on its FX and universal lines, which currently use Barber-Colman controls.

The company also plans to unveil its first all-electric machines sometime next year. Gerry Sposato, director of sales and marketing, says this new family will start with a 65-tonner and probably will range up to 300 tons.

HPM is looking to add vertical presses to its stable through acquisition and partnership. Negotiations for such a move are under way.

New plans for sheet

In the extrusion area, HPM is manufacturing a new pre-engineered extrusion sheet line. The new Universal Packaging Sheet line will be a complete manufacturing cell engineered to closely match the needs of the thermoformed packaging market.

HPM also makes custom sheet systems that can produce 30 ft wide sheet at thicknesses up to 2 in. In addition, HPM offers a pre-engineered line of extruders designed for pipe, tubing, and profiles. Prodex extruders come in sizes of 2, 2.5, and 3.5 in. HPM also makes single-screw, high-speed color-compounding systems and custom extruders from 2 to 15 in.

Related Content

Auto-Profile System for Blown Film Rotating Dies

NPE2024: New technology can slash gauge variation by 50%.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

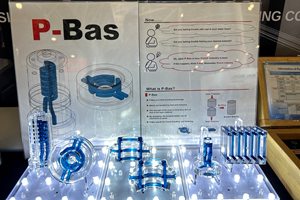

Read MoreBonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

Read MoreExtrusion Veteran Scuralli Starts Sales Rep Firm

Former owner of Wayne Machine & Die to represent suppliers of extrusion systems and components.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More