New Screw Design for Long-Glass Microcellular Foam Molding

A combination of microcellular foam molding and long-glass fibers offers new potential for injection molding to penetrate large structural automotive parts such as door-module carriers, brackets, and front-end systems.

A combination of microcellular foam molding and long-glass fibers offers new potential for injection molding to penetrate large structural automotive parts such as door-module carriers, brackets, and front-end systems. Such components remain mostly in metal due to high stiffness and impact requirements. “Door modules are used to support the door lock, motors for the window and related mechanics, plus the speaker systems and perhaps the arm rest as well. Hence, only a very stable part can be the platform for these sub-components,” says David Bernstein, president of Trexel Inc. His firm supplies systems with the patented MuCell microcellular foaming technology and has just developed a new screw design that preserves glass lengths far better than previous screws designed for MuCell. The result is a molding method that provides high mechanical properties, resin and weight savings, and low part stresses and warpage. What’s more, this approach is said to produce good results with long-glass-reinforced polypropylene in place of more expensive engineering thermoplastics.

The biggest challenge in molding long-glass fibers is keeping the fibers from being broken down and overcoming tendencies toward warpage in long and flat parts. Some injection machines have been developed with injection-compression capabilities to combat both fiber breakage and warpage. Injection-compression molding requires more complex tool designs and molding processes, Trexel notes. Although MuCell can be used beneficially with injection-compression, Bernstein says the warpage-reducing effect of the microcellular process, together with the new LGF screw design, should permit molders to make structural parts with more traditional molding approaches.

Another approach is so-called direct long-fiber thermoplastic (D-LFT) technology that involves compounding long glass with resin in-line with injection-compression molding. These machines are designed specifically for producing parts containing long-glass fibers and having minimum warpage, but such a system requires a high capital investment and may require high production volumes to justify its use.

Producing structural parts with a standard press remains much more difficult, says Levi Kishbaugh, Trexel’s v.p. of engineering. Standard screw designs tend to break glass fibers during the plasticating and/or injection phase. Shorter fibers lower the structural properties of the part. In addition, molders using standard injection presses often attempt to fight warpage tendencies by lengthening the holding and packing times at the cost of adding to the overall cycle time.

Long glass, standard press

The MuCell process always required a modified screw design to ensure good mixing of the supercritical gas (usually CO2 or nitrogen) with the resin. Bernstein says the standard MuCell screw has not been suitable for long-glass molding because it causes excessive glass breakage. Trexel’s new Long Glass Fiber Screw design is aimed to minimize damage to reinforcements on standard injection presses. When the LGF screw is coupled with the MuCell microcellular process it reportedly allows production of large structural parts with dramatically reduced warpage as well as high retention of properties, weight savings and cycle-time reduction. “We think the new screw design will increase the pace of the implementation of glass-filled plastic parts in these structural applications,” says Bernstein.

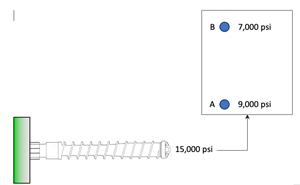

The new MuCell LGF screw design has a lower compression ratio of 2:1 rather than the 2.5:1 ratio of standard MuCell screws. In addition, the number of flights in the wiping and mixing sections of the screw have been reduced from six to four in order to reduce shear on the material. The screw design also uses wider mixing cuts (breaks in the flights) and replaces a ball check-ring design with an engaged check ring for improved process control.

One of the advantages claimed for the MuCell process is its tendency to eliminate warpage. When the polymer infused with supercritical gas under pressure expands in the mold, it fills the cavity without the stresses and nonuniform shrinkage often induced by high packing pressures. The MuCell process reportedly reduces the incidence of part warpage by a factor of five. It also eliminates sink marks, and can reduce clamp tonnage requirements by up to 40%, according to Trexel.

What’s more, MuCell foaming reduces material and weight savings by 5% to 12% with nominal property loss, and typically cuts cycle times by 10% to 20%, the company reports. In addition, the MuCell process can be turned off and the machine used as a standard injection press.

The LGF screw is said to be compatible with either D-LFT (in-line compounding) processes or molding precompounded long-glass pellets. (The MuCell process is said to be even easier to implement on a D-LFT system.) The screw can be used with any injection machine whose supplier is licensed to offer the MuCell process. The location of supercritical gas injection has not changed, so it is possible to switch between a standard MuCell screw and an LGF screw.

To date Trexel has tested the new LGF screw with long-glass PP and nylons 6 and 66, though company officials say the screw can be used with virtually any resin. The tests used Ticona’s Celstran long-glass pellets. In molding trials with 40% long-glass PP, MuCell parts showed a five- to six-fold reduction in warpage compared with unfoamed parts, according to Trexel’s Kishbaugh.

Trexel is currently designing the screw in sizes larger than 50 mm, aiming it for larger parts. Trexel does not recommend its use with unfilled materials. The standard MuCell screw is preferred for unfilled resins.

Trexel has entered into a collaboration with Engel to install MuCell technology and a 120-mm LGF screw on a 1000-ton Engel Duo two-platen press. This machine has patented software and hydraulic options for “coining” (injection-compression) and platen parallelism control. The press will be installed this month at Engel’s new technical center and training facility in York, Pa., to provide customer trials and demonstrations of the new technology.

Related Content

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreUse These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More