Nanolayers Enter Blow Molding

Technology mirrors Dow's recent development in blown film.

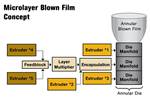

Dow Chemical Co., Midland, Mich., has adopted nanolayer technology developed for blown film (the film technology was discussed in our June issue). At the recent SPE ANTEC in Boston, a paper by Dow’s S. Crabree, J. Dooley, J. Robacki, P.C. Lee, R. Wrisley, and C. Pavlicek detailed technology that used feedblock and flow-divider technology more common in flat-die extrusion, as well as a specially configured die head to produce blow molded bottles containing more than 30 layers.

Related Content

-

Blow Molder with a Mission: CKS Packaging Shares Gains Of Its Phenomenal Growth

From three machines in 1986 to 27 plants nationwide today, this family-owned processor has prospered through unwavering customer service, committed employees and dedicated service to its community.

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.