‘Mini’ Low-Pressure Injection Machine Makes Large, Thick Parts at Low Cost

It can mold 70-lb parts 1 in. thick using 100% regrind, and it can reproduce micro surface detail. Add to that its small size, frugal energy consumption, and zero upfront cost.

What if you could satisfy short- to medium-run injection molding needs with the capability of a 500-ton press, in a machine that uses one-tenth as much energy and can fit on a large office desk? What if you could do that with no capital investment for the machine? And what if that machine would allow you to mold 100% regrind into parts that are stronger than the virgin originals?

If that sounds like an attractive proposition, those are just a few of the benefits cited for a new line of low-pressure injection molding machines being launched by Omachron Technologies in Pontypool, Ont., a new name in plastics extrusion and molding machinery, headed by Wayne Conrad, who calls himself “chief scientist and also president.” Omachron recently came out with a line of small extruders (see last month’s Keeping Up section) that also serve as the plasticating section of its molding machines. After seven years in development, the first commercial models of those presses are being built now for a handful of initial customers. The company is expanding capacity to serve a broader molding audience by the end of the year.

Omachron Technologies (omachrontechnologies.com) is the machine-building and moldmaking arm of Omachron Science, Conrad’s 30-year-old R&D company with 750 patents in fields as diverse as satellite communications, personal watercraft, and appliances (omachron.com). Another subsidiary is Omachron Plastics, which acts as a test bed for the company’s machinery, using it to produce the Plasti-Block line of machineable sheets, rods, tubes, blocks and custom shapes (plastiblocks.com).

‘THE POWER OF SMALL’

Omachron’s commercial motto is “The Power of Small,” referring to empowering small ┤ˇ¤ˇ┤ź├Żes to tackle big projects with low capital investment, using small-footprint machines with lower power consumption. Such machines make possible “distributed manufacturing” close to customers for the machines’ output, even in rural areas.

There’s nothing small, however, about the capacity of these molding machines. Conrad says the first model on the market can mold parts weighing up to 70 lb and measuring 24 in. wide × 36 in. tall × 1 in. thick. Conrad likes to “spec” his machines conservatively. This month, he says, Omachron Plastics will mold PE parts up to 140 lb. The firm also has orders for parts measuring 12 × 12 × 6 in. And an accompanying photo shows molded HDPE 2 × 4 in. planks 4 ft long.

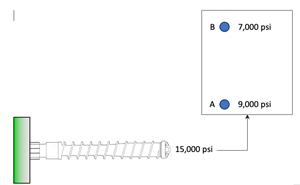

The secret to all this is a process sometimes called “intrusion molding,” whereby the mold is filled by extrusion rather than by injection of a pre-plasticated shot of melt. According to Conrad, this method has the benefit of low pressure, low melt temperature, and very low molded-in stresses. Typical filling pressures are 100 to 300 psi, and final packing pressures run 600 to 900 psi. Conrad cites the example of molding ABS with typical process temperatures 5° to 15° C (9° to 27° F) lower than is recommended by the material supplier—“And we still get perfect parts.”

Omachron’s machines have molded LLDPE, HDPE, PP, rigid PVC, ABS, nylon, acetal, UHMW-PE, PEEK and PPS. Conrad says it’s possible to mold ABS, PVC and HDPE to very nearly the same dimensions in the same tool, regardless of the different materials’ shrinkage. That’s because his machines fill continuously during packing, through a heated inlet, so as to compensate for shrinkage during cooling in the mold.

That also partly accounts for Omachron’s success in molding 100% regrind. For example, Conrad says his machines molded reground PVC plumbing fittings into new fittings that were 15% stronger than the originals, due to low molded-in stress. After five regrind cycles, the molded fittings still retained 10% higher strength than the virgin originals, owing to the low thermal stress of intrusion molding—without introducing any additional stabilizer additives.

Conrad notes that besides molding huge parts, his process also ensures accurate reproduction of part surface features down to micro scale—for example, capillary microstructures measuring only a ten-thousandth of an inch (0.001 mil).

SMALL FOOTPRINT

Another benefit of the intrusion molding process is that it greatly reduces the equipment size needed to mold large parts. Three extruders are available for the plasticating section—1 in. diam., 18:1 L/D and 1.25 in., 24:1 or 36:1 L/D. With optimized screw designs and electric motors, they require only 2 to 5 hp to produce from 10-25 lb/hr for the smallest size up to 100-120 lb/hr.

The clamp and mold are typically much larger than the extruder. The machine is all-electric with a proprietary, ballscrew-driven clamp design. The clamp has 144 tons of closing force and 5 tons of opening force. “No individual part of the machine weighs more than 60 to 70 lb,” says Conrad. “And it’s totally modular, so parts are easy to replace.”

Molds are made of aluminum, which reduces weight, cost, and time for machining. (The molds for the 4-ft planks mentioned above were built, and initial parts produced, only five days after receiving the order.) Some molds are ceramic-based with a flame-sprayed nickel coating for heat transfer and corrosion protection. Molds can be mounted on a pushcart for installation—“One person can do it safely,” Conrad asserts.

The machine with mold is about 3 × 7 ft—or about the footprint of a large office desk—and weighs around 2.5 tons without the mold. This is so compact that a molding operation can be established in a facility of 1000 to 2000 ft2, according to Conrad.

Low power requirement also characterizes these machines, which can run on single-phase, 220V/80-89A power (or three-phase if desired).

Omachron’s machines are available for lease, not sale, so there is no upfront investment (except for molds and perhaps auxiliaries like water cooling). Typical monthly lease costs are $5000 to $6000 (USD).

On the other hand, these machines are not for fast-cycle molding. For large, thick parts, molding cycles can range from 10 min to 1 hr.

Conrad says Omachron is building its first 10 commercial machines, which occupies its full production capacity right now. But next year it expects to expand to production of 50 to 100 machines.

Related Content

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More