How Urgent Plastic Services Lives Up To Its Name

If you need prototype or short-run parts fast, Urgent Plastic Services can make the mold and the parts in as little as two to four weeks instead of the 10- to 12-week average for other firms.

If you need prototype or short-run parts fast, Urgent Plastic Services can make the mold and the parts in as little as two to four weeks instead of the 10- to 12-week average for other firms. Based in Rochester Hills, Mich., Urgent employs 65 people and generates $12 million to $15 million in revenue. It makes about 1000 steel or aluminum prototype molds a year. For such a small outfit to be so productive it has to concentrate on reducing bottlenecks in every phase of the process, says David Krajci, operations manager. That means streamlining tool design, tool making, and molding.

Focus on debottlenecking

“We have a very organized production-line system, and we take a cell-manufacturing approach,” says Krajci. Personnel are dedicated to areas like CAD, EDM, milling, finishing and assembly, molding, and quality control. Urgent streamlined its operations to the point that there are not a lot of questions to be asked when a new project comes in. “Everyone on staff is well acquainted with our capabilities, and set-ups for each step are nearly the same. This makes us more efficient,” says Krajci.

“It starts with being able to quickly access the numerous CAD files that come in,” Krajci notes. Those files are downloaded from the company’s internet FTP (file transfer protocol) site. Urgent maintains more than 10 different CAD programs. That is many more than most other firms would use, owing to the cost and training requirements, but Urgent sees this as a key investment strategy. “We can translate any CAD file into STEP or IGES files that can be exported into our own CAD system for the actual mold-design work. We do not have to outsource the files for translation or repair, so we are not penalized by any time delays or errors,” says Krajci.

The company has six full-time mold designers. “Other shops may just have one or two designers, but we have an established department in which each person has a high degree of technical knowledge and is able to bring new ideas into the process,” Krajci adds.

Urgent gains another edge when it is time to fabricate the tool. Other moldmakers may have to put jobs into queues because they do not have enough milling ma chines. But Urgent has six carbon EDMs, five wire EDMs, and 14 CNC mills, of which four are high-speed units that work 15 times faster than standard mills. There is no waiting to get a job started, and all of the tooling components can be cut simultaneously.

Urgent can also rely on fabricating capacity at its two sister companies, 3 Dimensional Services, Rochester Hills, Mich., and Urgent Design and Manufacturing, Lapeer, Mich., which have 24 NC mills between them.

To streamline communication of data between tool design and manufacturing, Urgent uses Delcam’s PowerShape CAD for design and PowerMill CAM software for machining. After milling, the steel or aluminum tools are finished by a dedicated finishing staff and the tool is put on one of 13 injection presses ranging from 30 to 1500 tons. Urgent maintains excess press capacity, and all its machines are kept in “ready-to-go” status, so molding jobs are never kept waiting. The company typically runs six presses in a day and up to three jobs on each machine. The presses are fitted with Master Unit Die mold frames that allow quick interchange of cores and cavities. Urgent can change a mold in 15 to 45 min.

Short runs, too

Urgent makes primarily aluminum molds and stocks about four months’ worth (350,000 lb) of material. But the biggest chunk of Urgent’s revenue comes from steel tools that it builds for military applications that use engineering resins like polycarbonate, polyetherimide (GE’s Ultem), or PEEK. For the military, Urgent often molds not just prototypes but the full production run. They can make from 15 parts to up to 20,000.

Urgent says precise temperature control during molding helps to gauge the accuracy and performance of the tool. For military and other jobs with high-temperature resins, Urgent uses hot-oil mold-temperature controllers and Paratherm HE heat-transfer fluid from Paratherm Corp., Conshohocken, Pa. Urgent has used Paratherm HE for five years without ever changing the fluid and has experienced no problems with fluid breakdown or sludging.

Related Content

Conair Names New Head of Customer Care

Jared Helfrich to direct the efforts of the machine builder’s growing customer care group, combining its existing parts and service and repair organization with a new range of fast-growing customer services.

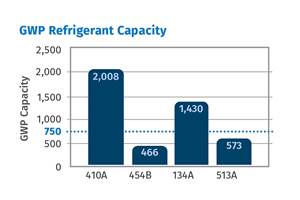

Read MoreTemperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

Read MoreKeeping Process Water Cool and Efficiency High in the Desert

Rehrig Pacific turned to Process Cooling Systems to create a high-efficiency plantwide process-cooling system for its newest injection molding facility outside of Phoenix.

Read MoreIndustry Vet Duff Joins ACS Group

With 37 years of experience on both machinery and processor side, Michael Duff to handle aftermarket ´óĎó´«Ă˝ for auxiliary equipment manufacturer.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More